Cured-in-place pipe lining seals the deal

Originally Published 8/24/2016

METHOD IS ALTERNATIVE TO DIGGING IN STREETS

IN THE DECADES FOLLOWING INSTALLATION, the pipes and manholes that make up Nashville's system deteriorate, resulting in cracks and other defects along the pipe and at pipe joints. These defects allow excess rain or groundwater, known as infiltration and inflow, to enter the sewer system and can lead to sanitary sewer overflows. To combat this problem, the defective pipes can be unearthed and replaced, which can be quite disruptive, or they can be repaired in place through sewer system rehabilitation.

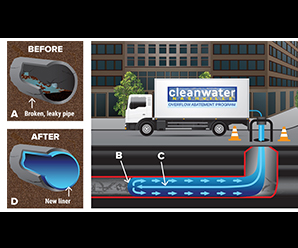

Cured-in-place pipe (CIPP) lining is one of several sewer rehabilitation methods used to repair leaking or structurally unsound existing pipelines. Little to no digging is involved in this trenchless process, making for a more cost-effective, environmentally friendly process that is completed more quickly and with fewer impacts and disruptions than pipe replacement. CIPP is the primary sewer pipe rehabilitation method used by Metro Water Services (MWS) since the early 1990s. CIPP results in a seamless, tight-fitting, corrosion-resistant liner within the original host pipe that improves pipe hydraulics and restores the pipe to a structurally sound condition.

CIPP consists of a flexible felt tube which is saturated with gel resins. The cured-in-place pipe liner is stretched inside the defective pipe between two manholes. After the liner is placed inside the pipe, the resins within the liner are activated, typically using recirculated hot water or steam from a boiler truck. This creates a chemical reaction that converts the flexible felt liner into a rigid, solid pipe that adheres to the interior of the defective host pipe, resulting in a new pipe within the old pipe.

After the CIPP curing process is complete, which may take from a few hours for small diameter pipes to 24 hours or more for large interceptors, the connections for service laterals to homes or businesses are restored internally using a robotically controlled cutting device. Typically a new access location (cleanout) is installed at the property line unless surface features make excavation difficult. Depending on the location of the service lateral, the portion of the service line between the property line and the main sewer line may be rehabilitated through CIPP or replaced through excavation.

CIPP requires diversion pumping of the sewer flow in the existing pipeline while the liner is being installed. This may involve temporary pumps and pipes on the top of the ground from the upstream to the downstream manholes. For larger diameter pipes, preparing the pipe for lining may take longer than the actual lining process. A number of trucks and some large equipment are required to perform the work, and temporary access roads in easements may be necessary.